New Study Highlights Need for Advanced Scanning Capabilities

On-time delivery, increasing shipping speed, reducing labor costs, and perfect order rates are top concerns for warehouse operations

CHICAGO and MUNICH, April 9, 2024 – A recent VDC Research study on behalf of ProGlove highlights the need for advanced scanning solutions. The new whitepaper identifies on-time delivery/shipping speed, reducing labor costs, and improving order accuracy rates as the top concerns for warehouse operations. “Logistics Operational Pressures Driving Need for Advanced Scanning Solutions” discusses how companies can address these and other challenges.

The Critical Role of Advanced Scanning

Barcode scanning remains a cornerstone of materials management and logistics. But as this recent VDC Research study shows, advanced scanning technologies are needed to help operators keep up with the increased pace of processes. Accurately and orderly scanning the correct barcodes, especially when dealing with multiple labels with multiple barcodes, is a challenge in the context of cross-docking, receiving, putaway, storage, picking, shipping, and many other use cases. This is especially true for the above tasks that require the barcodes to be transmitted in a specific order to the enterprise management application. Warehouse operations need to address these issues to remain efficient and productive while not unduly impacting the well-being of their employees.

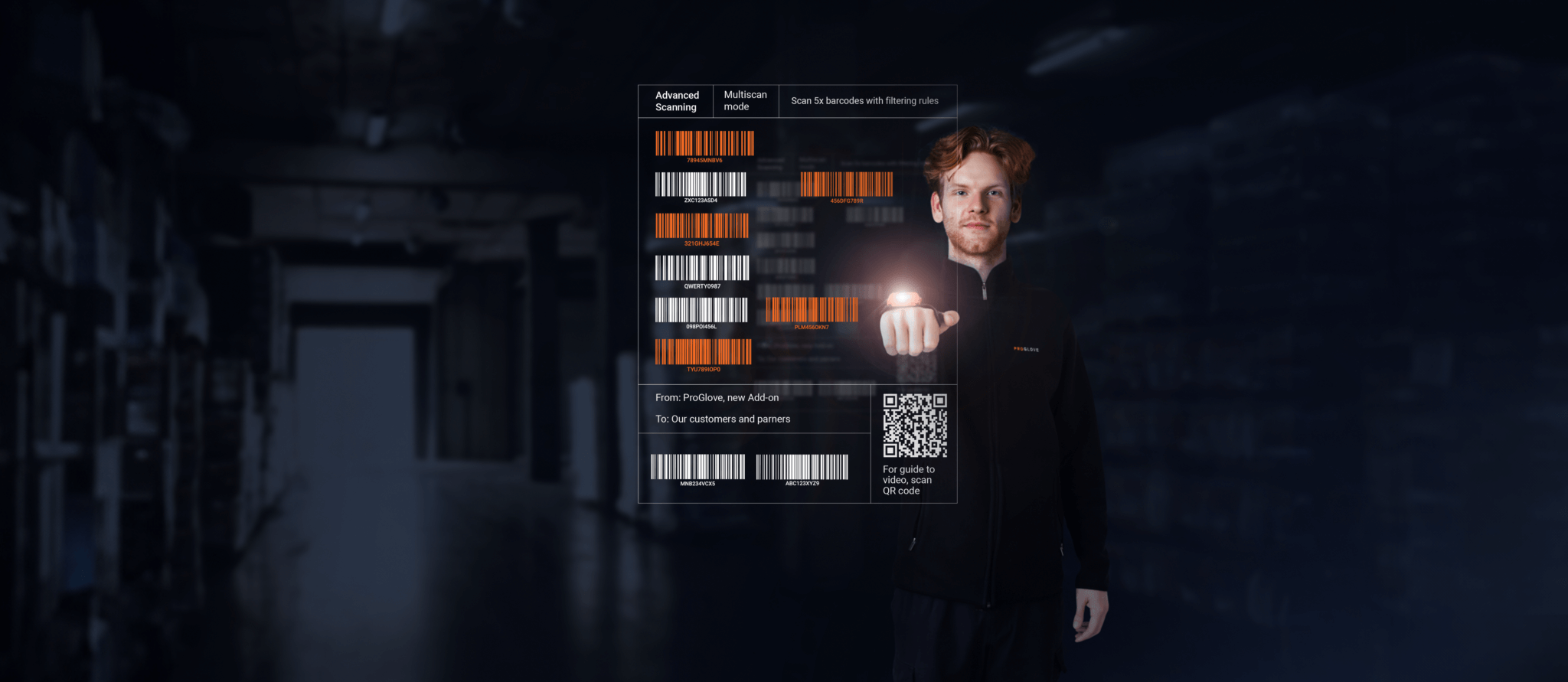

The VDC Research analysis examines how ProGlove’s Multiscan and Continuous Scanning software features can help companies address the challenges outlined above. Multiscan focuses on control and precision. Users can add filters, implement rules, develop sorting algorithms, and predefine the order in which barcodes are transmitted to the WMS/ERP without requiring system customization. Using these rules, the built-in software logic allows users to scan up to 5 barcodes simultaneously and send them to a back-end application in a predetermined order without worrying about accidentally scanning the wrong codes.

Continuous Scanning focuses on volume and speed. The feature allows users to capture up to ten barcodes in a single scan by holding the trigger in and hovering over the barcodes in the desired order. When the order of barcodes is less important, the continuous scanning feature allows workers to quickly collect and transmit data to the warehouse management system up to ten times faster.

Empowering Warehouse Efficiency Through Human-Centered Technology

“There is no doubt in my mind that using people-centeric technology is the easiest way for warehouse operations to deal with the pressures they face,” said Stefan Lampa, CEO of ProGlove. “It provides the necessary tools to make processes safe and reliable while allowing workers to be hyper-productive and healthy. These advancements are critical not only to increasing shipping speeds and reducing turnover, but also to shortening training periods, ensuring that the journey from technology deployment to tangible return on investment is as short and productive as possible.”

The VDC Research whitepaper “Logistics Operational Pressures Driving Need for Advanced Scanning Solutions” is available for download at: www.proglove.com/vdc-advanced-scanning

About ProGlove

Founded in 2014, ProGlove provides industrial wearable scanning solutions. With its hardware and software products, ProGlove increases productivity, safety and quality for more than 2,000 customers in warehousing, logistics, manufacturing and retail. ProGlove solutions enable users to capture and analyze data quickly and easily. ProGlove’s customers include well-known organizations such as BMW, DHL, Gap Inc. and Lufthansa Technik Logistik Services. ProGlove is headquartered in Munich, Germany, with additional offices in Chicago (USA), Coventry (UK) and Belgrade (RS). The company employs more than 350 people from over 30 countries. More information is available at: www.proglove.com